FERRO CHROME

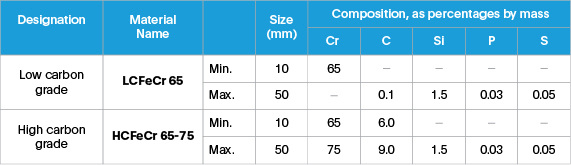

Ferrochrome, or Ferrochromium (FeCr) is a type of ferroalloy, that is, an alloy between chromium and iron, generally containing 60% to 65% chromium. It is produced in an energy intensive process in electric furnaces from chrome ore, iron ore and coal. FeCr is used in the production of stainless steel, special steel and castings. Ferrochrome is divided up in three main products which are Low Carbon FeCr, Medium Carbon FeCr and High Carbon FeCr.

Ferro silicon

Ferrosilicon, also known as ferrosilicon alloy. It is an alloy composed of silicon and iron in a certain proportion. Due to the different silicon content, the commonly used grades of ferrosilicon are: ferrosilicon 65, ferrosilicon 70, ferrosilicon 72, ferrosilicon 75.

Ferrosilicon is used as a source of silicon to reduce metals from their oxides and to deoxidize steel and other ferrous alloys. This prevents the loss of carbon from the molten steel ferromanganese, spiegeleisen, calcium silicides, and many other materials are used for the same purpose.[5] It can be used to make other ferroalloys. Ferrosilicon is also used for manufacture of silicon, corrosion-resistant and high-temperature-resistant ferrous silicon alloys, and silicon steel for electromotors and transformer cores. In the manufacture of cast iron, ferrosilicon is used for inoculation of the iron to accelerate graphitization. In arc welding, ferrosilicon can be found in some electrode coatings.

Ferrosilicon is a basis for manufacture of prealloys like magnesium ferrosilicon (MgFeSi), used for production of ductile iron.Ferrosilicon is also important as an additive to cast irons for controlling the initial content of silicon.

FERRO MOLYBDENUM

Ferro Molybdenum is a hardening agent and is found in many alloy steels that are heat-treatable. Molybdenum prevents corrosion in stainless steels and alloy steels. The steel industry is the largest user of molybdenum, accounting for approximately 80% of molybdenum mined in the world.

Molybdenum is used to improve mechanical and physical properties of all kinds of steels. Applications for our products include additions to constructional alloy steels, tool and high speed steels, stainless steels, super alloys and cast irons as well as cast steels.

Applications

Ferro molybdenum is used in ferrous alloys manufacturing. Different industrial sectors select Ferro molybdenum based on the molybdenum content to use it in manufacturing of military hardware, machine tools & equipment, load-bearing components, rotary drills and refinery tubing..

Stainless steel and heat-resistant steels that contain ferro molybdenum are used in several plant, equipment and systems, It is also added in large amount in tool steels to be used in ball & rolling mills, large drill bits, high-speed machining components, dies, chisels, etc.

FERRO TITANIUM

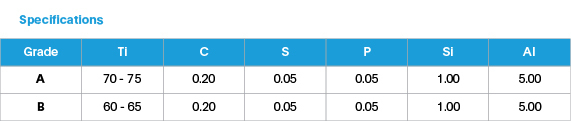

ferrotitanium is a ferroalloy, an alloy of iron and titanium with between 10–20% iron and 45–75% titanium and sometimes a small amount of carbon. It is used in steelmaking as a cleansing agent for iron and steel; the titanium is highly reactive with sulfur, carbon, oxygen, and nitrogen, forming insoluble compounds and sequestering them in slag, and is therefore used for deoxidizing, and sometimes for desulfurization and denitrogenation. In steelmaking, the addition of titanium yields metal with finer grain structure.

Steel manufacturing plants make use of FeTi alloy as stabilizers for the prevention of formation of chromium carbide at the grain boundaries. This can improve malleability in carbon steels, thereby increasing its versatility. It also serves the manufacture of low carbon steel for producing steel sheets. Foundries use FeTi for the fusing the molten metal with titanium to impart excellent strength and quality to it without interfering with other ratio

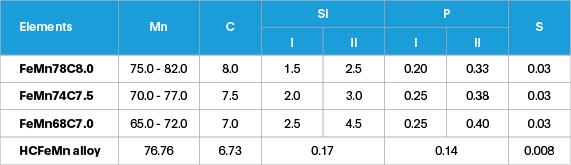

FERRO MANGANESE

Ferro manganese is an alloy composed of manganese and iron and is produced by blast furnaces or electric furnaces. High carbon ferro manganese produced by electric furnace is mainly used as deoxidizer, desulfurizer and alloy additive for steelmaking. In addition, with the progress of low carbon ferro manganese production technology, high carbon ferromanganese can also be used to produce low carbon ferro manganese.

Ferro manganese is very important in steelmaking and casting. It can improve the hardness, strength and wear resistance of steel, and improving the cutting characteristics of castings.

Application

- Ferro manganese is an indispensable cheap deoxidizer and desulfurizer in the steelmaking industry.

- MnS generated after desulfurization of ferro manganese can improve the cutting performance of castings.

- High carbon ferro manganese is used as a raw material for the production of low carbon ferroalloys.

- Improve the mechanical properties of castings, and increase the hardness and strength of castings after hot rolling.

- Used as an inoculant and nodulizer for cast iron, prevent the formation of carbides, improve the properties of cast iron.

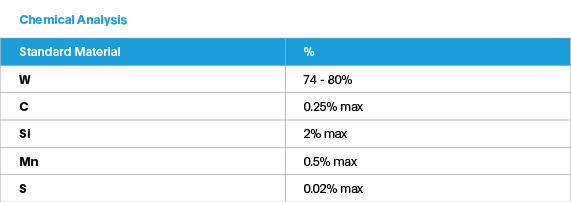

FERRO TUNGSTEN

Tungsten is an important alloying element in high-speed and other tool steels, and is used to a lesser extent in some stainless and structural steels. Tungsten is often added to steel melts as ferrotungsten, which can contain up to 80% tungsten Commercial ferro-tungsten contains between 75 and 85% W. It has a steel grey appearance and a fine-grained structure consisting of FeW and Fe2W. It is supplied in 80-100 mm lumps.

Properties

One of the primary benefits of adding Ferro Tungsten to an alloy is to increase the alloy’s melting point, making it suitable for aerospace applications as well as welding applications. Additionally, by adding Ferro Tungsten to an alloy, one can take advantage of tungsten’s unique electrical capabilities as a conductor.

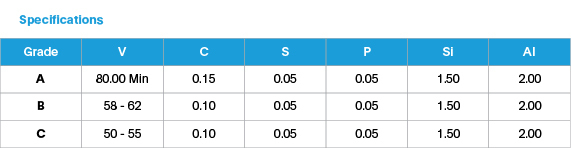

FERRO VANADIUM

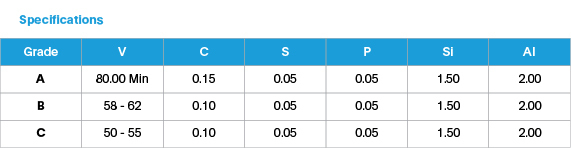

Ferrovanadium is a universal hardener, strengthener and anti-corrosive additive for steels like high-strength low-alloy (HSLA) steel, tool steels, as well as other ferrous-based products.

Ferro Vanadium when added to an alloy gives stability against alkalis as well as sulphuric and hydrochloric acids. Ferro Vanadium also helps in avoiding of Corrosion to Steel. It also helps in increasing of Tensiile Strenght of Steel, Casting & Welding Electrodes.

It has significant advantages over both iron and vanadium individually. Ferrovanadium is used as an additive to improve the qualities of ferrous alloys. It is also used to improve the tensile strength to weight ratio of the material.

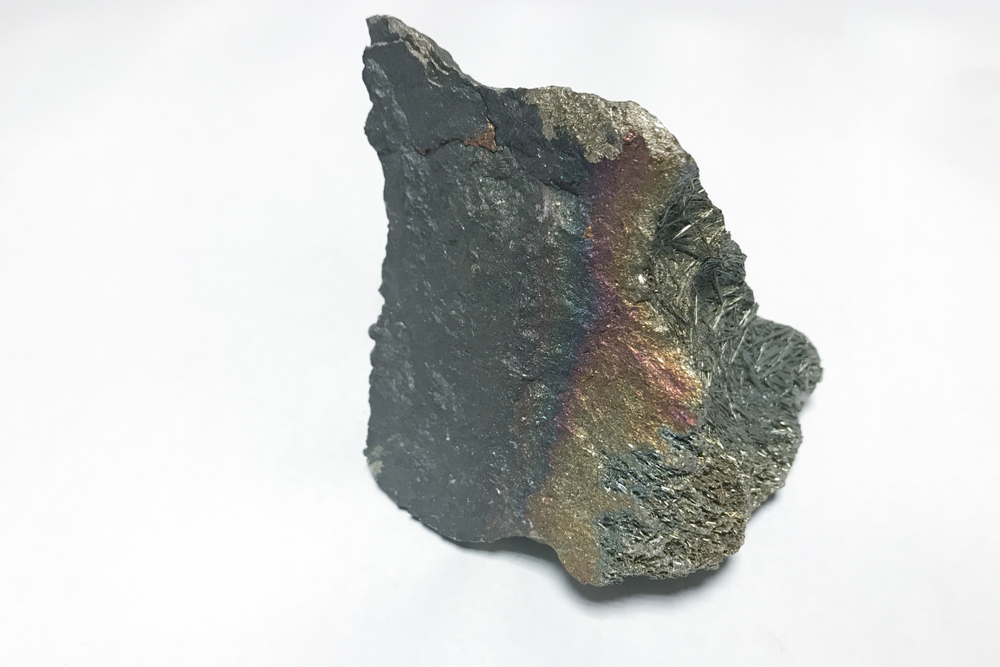

FERRO PHOSPHORUS

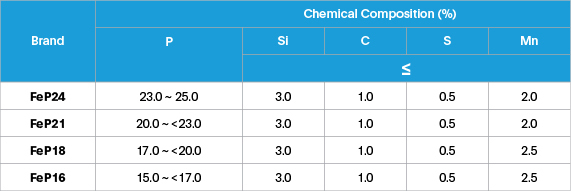

Ferrophosphorus is a ferroalloy, an alloy of iron and phosphorus. It contains high proportion of iron phosphides, During the production of steel, Ferro Phosphorus is generated as a by-product. It skims from the top of the slag in the conversion process of pig iron.Phosphorus is a Ferro alloy composed of iron and phosphorus in which the phosphorus content defines the quality of the product, ranging between 23% and 32%.

Applications:

This iron and phosphorous combination has several applications, for instance it can be used:

- The manufacturing of phosphorous castings

- The manufacturing of High-Strength special Steels Low-Alloy (HSLA)

- Its ability to be used as a deoxidizing agent in steels

- As a manufacturing drying agent.

- As an ingredient in high-strength low-alloy steel

- As a dehydrating agent for removing water at the time duration of the alloy formation